INO Prozess- & Transportbänder Endlosverbindungsarten

EndlosverbindungsartenDie INO Prozess- & Transportbänder werden endlos verschweißt oder mechanisch verbunden.

Unsere Verbindungsverfahren finden Sie hier:

I. Geschweisste Verbindungen

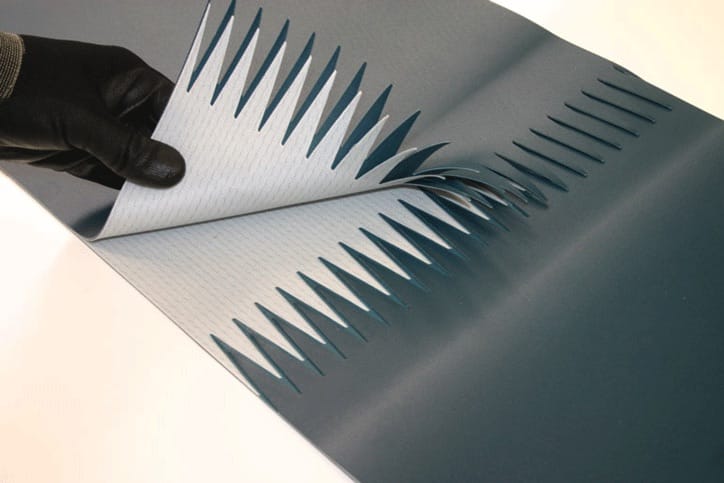

01 Fingerverbindung

In die Verbindungsenden werden hier Finger gestanzt, die anschließend zusammengeheftet und mittels Druck und Hitze verschweißt werden. Dieses Verfahren eignet sich besonders gut bei einlagigen Bändern.

Details

| Verbindungslänge | 70 mm |

| Länge der Finger | 70 mm |

| Breite der Finger | 15 mm |

| geeignet für | INFAB, INPUR, INV, INVOR, INFIN, INHYT, INSIL |

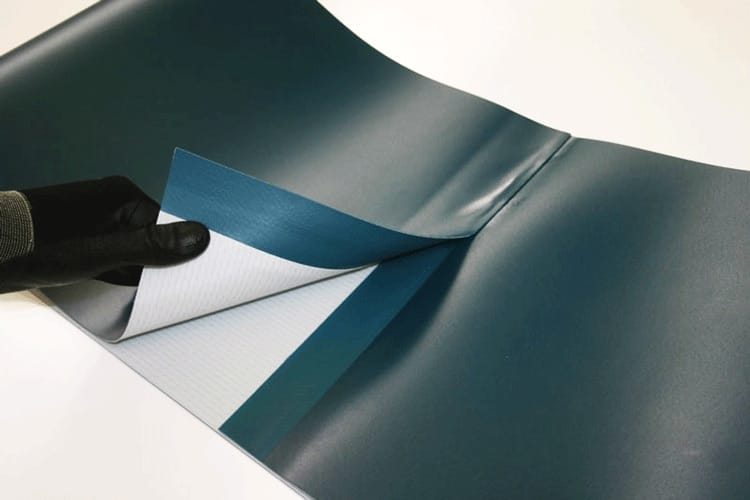

02 Überlappte Fingerverbindung

Wir empfehlen die überlappte Fingerverbindung. Hier werden die Verbindungsenden ebenfalls gestuft aufgespalten. Anschließend werden versetzt Finger in die Enden gestanzt, die dann zusammengeheftet und mittels Druck und Hitze endlos verschweißt werden.

Details

| Verbindungslänge | 100 (2×50) mm |

| Länge der Finger | 50 mm |

| Breite der Finger | 15 mm |

| geeignet für | INFAB, INPUR, INV, INVOR, INFIN, INHYT, INSIL (mind. 2 Lagen) |

03 Stufenverbindung

Bei der Stufenverbindung werden die Verbindungsenden gestuft abgespalten und deckungsgleich übereinander gelegt – allerdings in einem Winkel von 80° um einen schonenden Lauf um die Umlenkung zu gewährleisten.

Details

| Winkel | 80° |

| Verbindungslänge (2-lagig) | 40 mm |

| Verbindungslänge (3-lagig) | 80 mm |

| Bandtypen | INFAB, INPUR, INV, INVOR, INFIN, INHYT, INSIL (mind. 2 Lagen) |

04 Ausgeschärfte Verbindung

Bei unseren Gummi- und Filzbändern verwenden wir die ausgeschärfte Verbindung. Hier werden die Verbindungsenden in einem 80° Winkel schräg geschält, deckungsgleich übereinander gelegt und mittels Kleber und Druck endlos verbunden.

Details

| Winkel | 80° |

| Verbindungslänge | 80 mm |

| Bandtypen | INFELT, INRUB |

Limitationen: Es können nur thermoplastische Bänder verschweißt werden. Alternativ werden Bänder geklebt. Minimale Bandlänge: 800 mm, Maximale Bandbreite: 3.000 mm

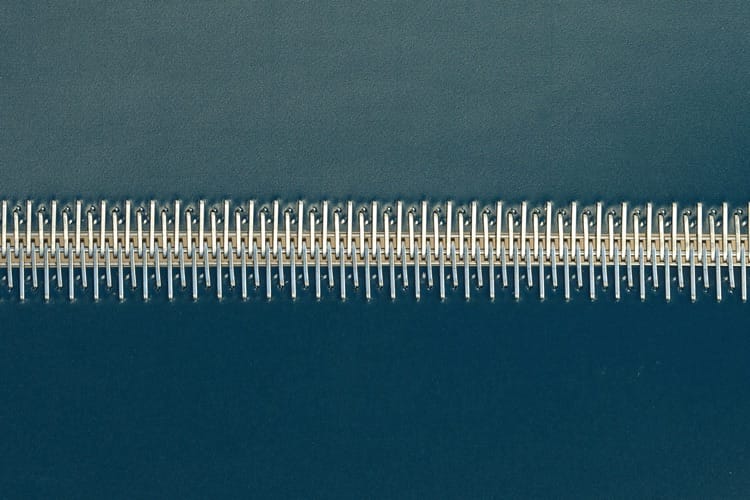

II. Kunststoffspiralverbinder

Für feine Anwendungen eignet sich der Kunststoffspiralverbinder hervorragend. Er kann für alle Typen verwendet werden.

III. Mechanische Verbindungen

Für Anwendungen, die weder den Einbau eines endlosen Bandes noch das Verschweißen in der Anlage erlauben, können INO Prozess- und Transportbänder mit mechanischen Verbindern ausgestattet werden.

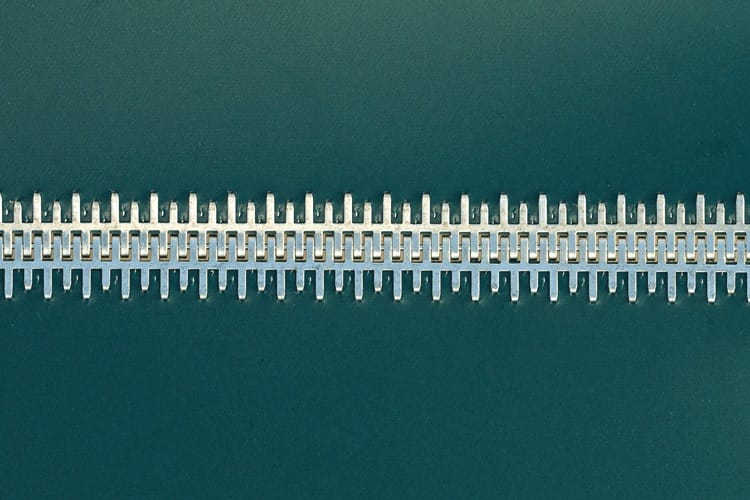

01 Haken in runder Ausführung

In die Bandenden werden Metallhaken eingepresst, sodass das Band durch einen Metall-Stab endlos verbunden werden kann. Bei geprägten Bändern wird die Deckschicht entfernt, damit die Haken nicht über die Bandoberfläche hinausragen.

Details

| Type | Bandstärken [mm] | Hakenlänge* [mm] | min. Trommel-Ø [mm] |

| A36 SLXSP- SS-600 | -1,5 | 600 | 25 |

| A36 SP- SS-600 | 1,5-2 | 600 | 50 |

| A36- SS-600 | 2-3 | 600 | 50 |

| A40- SS-600 | 3-4 | 600 | 50 |

02 Haken in flacher Ausführung

In die Bandenden werden Metallhaken eingepresst, sodass das Band durch einen Metall-Stab endlos verbunden werden kann. Bei geprägten Bändern wird die Deckschicht entfernt, damit die Haken nicht über die Bandoberfläche hinausragen.

Details

| Type | Bandstärken [mm] | Hakenlänge* [mm] | min. Trommel-Ø [mm] |

| G001A- SS-300 W | -1,5 | 300 | 25 |

| G005A- SS-1200 W | 1,5-2 | 1200 | 40 |

| G005A- SS-1500 W | 2-2,5 | 1200 | 40 |

| G006A- SS-1200 W | 2,5-3,5 | 1200 | 50 |

03 Plattenverbinder

In die Bandenden werden Metallhaken eingepresst, sodass das Band durch einen Metall-Stab endlos verbunden werden kann. Bei geprägten Bändern wird die Deckschicht entfernt, damit die Platten nicht über die Bandoberfläche hinausragen.

Details

| Type | Bandstärken [mm] | Hakenlänge* [mm] | min. Trommel-Ø [mm] |

| RS62 Sj24 / 600 NCS | 1,5-3,2 | 600 | 50 |

| RS125 Sj24 / 600 NCS | 3,2-4,8 | 600 | 75 |

* Bei Breiten, die über die Hakenlänge hinaus gehen, werden die Haken nebeneinander angeordnet.

Fragen?

Rufen Sie uns an: +49 (0) 4153 55095 – 0 oder nutzen Sie unser Kontaktformular

Downloads

Die Downloads aller Kataloge und Broschüren finden Sie hier

Musterkatalog

Musterkataloge oder weitere Informationen können Sie hier anfragen